Lifting Eye Nut - CE Marked - DIN 582 - Stainless Steel

Lifting Eye Nut with Working Load Limit - Metric Thread - Forged A4-AISI Stainless Steel

Lifting Eye Nut - CE Marked - Stainless Steel

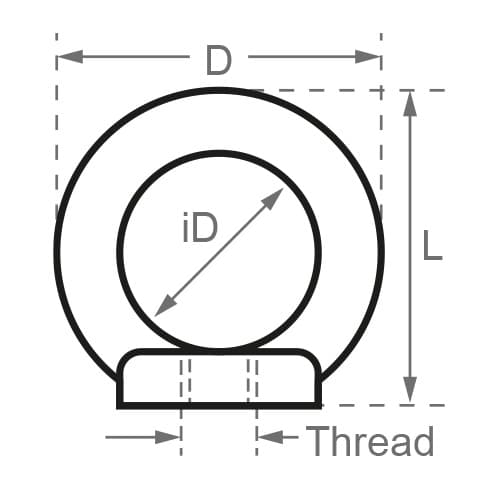

| Options | Thread | iD (mm) |

D (mm) |

L (mm) |

WLL (kg) |

Code | Price (inc VAT) | Quantity |

|---|---|---|---|---|---|---|---|---|

| M6 Lifting Eye Nut | M6 | 16 | 28 | 31 | 75 | EN-M6-WLL | £2.71 | |

| M8 Lifting Eye Nut | M8 | 20 | 36 | 36 | 140 | EN-M8-WLL | £3.46 | |

| M10 Lifting Eye Nut | M10 | 25 | 45 | 45 | 230 | EN-M10-WLL | £6.12 | |

| M12 Lifting Eye Nut | M12 | 30 | 54 | 53 | 340 | EN-M12-WLL | £8.34 | |

| M16 Lifting Eye Nut | M16 | 35 | 63 | 62 | 700 | EN-M16-WLL | £13.04 | |

| M20 Lifting Eye Nut | M20 | 40 | 72 | 71 | 1200 | EN-M20-WLL | £22.58 | |

| M24 Lifting Eye Nut | M24 | 50 | 90 | 90 | 1800 | EN-M24-WLL | £47.36 | |

| M27 Lifting Eye Nut | M27 | 60 | 108 | 109 | 2100 | EN-M27-WLL | £53.04 | |

| M30 Lifting Eye Nut | M30 | 60 | 108 | 109 | 3200 | EN-M30-WLL | £61.14 | |

| M36 Lifting Eye Nut | M36 | 70 | 126 | 128 | 4600 | EN-M36-WLL | £90.90 |

Tip: To view the product code and full product table on mobile please tilt your device to landscape.

Key Features:

|

316 grade stainless steel. |

|

Forged. |

|

Metric Thread. |

|

CE Marked. |

|

Quoted working load limit. |

High quality lifting eye bolt manufactured from forged A4 -AISI 316 stainless steel to meet DIN 582 specification.

Metric thread sizes: M6, M8, M10, M12, M16, M20, M24, M27, M30, M36.

Each eye nut is stamped with working load limit (WLL).

Working Load Limit

The working load limit (WLL) will only apply in axial direction and assume that the eye nut is screwed on completely and lies flat over the entire surface.

Eye Nut Safely Tips

To use stainless steel lifting eye nuts safely, follow these steps:

- Load capacity: Make sure to choose an eye nut with a load capacity that exceeds the weight of the item it will support. Do not exceed the maximum load capacity of the eye nut.

- Inspection: Regularly inspect the eye nut for signs of wear, corrosion, or damage. Replace any eye nuts that are showing signs of degradation.

- Installation: Ensure eye nut is securely attached to the surface and tightened to the appropriate torque.

- Attachment mechanism: Make sure to choose an attachment mechanism (e.g. shackle, hook, or rope) that is compatible with the eye size of the eye nut and has a load capacity that exceeds the weight of the item it will support.

- Use proper techniques: When using the eye nut, make sure to use proper lifting techniques to avoid putting excessive stress on the eye nut or the attachment mechanism.

- Avoid side loading: Avoid side loading the eye nut, as this can cause it to fail. Make sure the load is applied in a straight line with the eye nut.

- Regular maintenance: Regularly maintain and lubricate the eye nut and attachment mechanism to ensure their proper functioning and longevity.

Dimension Information:

PDF Data Sheet

Download Lifting Eye Nut Dimension Information

You may be interested in...

Lifting Eye Bolts - CE Marked - DIN 580.

General Purpose Eye Nuts - Stainless Steel

General purpose Eye Bolts - Stainless Steel