Stainless Steel Wire Rope Technical Information

Wire and Cable Stretch Characteristics - Modulus of Elasticity - Break Load

Stainless steel cables for any application

We stock an extensive range of stainless steel wire & cable. In 1x19, 7x7 and 7x19 constructions in AISI 316 marine grade stainless steel. Sizes 1.5mm to 19mm. We can plastic coat stainless cable to order.

Stainless steel cable & stainless wire rope is highly corrosion resistant & decorative. Excellent for marine rope rigging, stainless steel cable railing, architectural cables, cable balustrades and cable display systems.

1x19 Stainless Steel Wire Rope

1x19 construction stainless wire rope and stainless steel cable is non-flexible and has a high resistance to corrosion. Suitable for balustrading, stainless steel cable railing, yacht rigging & decorative applications where flexibility is not important.

View the full range7x7 Stainless Steel Wire Rope

Flexible 7x7 construction 316 marine grade stainless cable is suitable for tensioning, security cables, marine architectural use, stainless cable balustrading, stainless steel cable railing & decorative applications. Cable diameters below 2mm are very flexible.

View the full range7x19 Stainless Steel Wire Rope

Highly flexible 7x19 construction 316 stainless Stainless Steel Wire Rope is suitable for most running load applications and numerous applications such as security cables and winch cables.

View the full rangeStainless Steel Wire Rope Assemblies

We can make up stainless cable assemblies with a large variety of Stainless Steel Wire Rope fittings. If you can't see what you need here please give our sales team a call.

View the full rangeTechnical Information

Recommended Minimum Diameter of Pulleys

If wire ropes run over pulleys, the working life can be extended by the right choice of pulley and suitable wire rope.

Pulley Diameter in mm for 7x7 construction wire rope = 42 x Rope Diameter (mm)

Pulley Diameter in mm for 7x19 construction wire rope = 25 x Rope Diameter (mm)

Stretch in Wire Ropes

Stretch is a characteristic of all wire ropes; constructional stretch initially (as the individual wires 'bed down') and then as conventional elastic stretch.

This permanent stretch can be as much as 0.1% for a 1x19 strand.

Elastic Stretch

Once a cable has bedded down it will obey Hookes Law; elastic stretch will be proportional to the load applied. Resistance to this stretch is determined by the modulus of elasticity.

Pre-Stressing

Where stretch is critical to the application, constructional stretch can be eliminated by pre-tensioning or pre-stressing. This can be carried out during manufacture or swaging.

Pre-stressing is usually only applicable on large bridge structures and is not necessarily appropriate on structures where rigging screws and tensioning devices are used to take up any stretch.

Elastic stretch can be calculated by the following formula:

Elastic Stretch = (W x L) / (E x A)

Typical values for E are:

Break Load Example

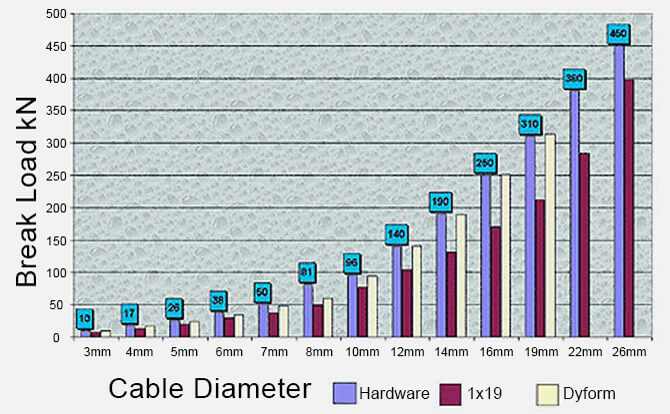

The graph shows typical breaking loads for our hardware compared against conventional 1x19 and Dyform 316 stainless steel cables.

It should be noted that stainless steel wire rope and strand will start to distort at around 50% of its breaking load. It is therefore advisable not to load cables to more than 50% of their breaking loads.

Factors of safety should always be applied when calculating maximum loading conditions. In cases of doubt, an engineer should be consulted to assess the loading and advise on suitable factors of safety to ensure that overloading cannot occur.

To convert kN to KgF divide by 0.009807. To convert kN to LbF divide by 0.004448.

Video: A guide to the different types of stainless steel wire rope

Stainless Steel Wire Rope - Demonstration of Different Types. What are the different types and properties of stainless steel wire ropes?